Would you like to learn more about us and our roots? Here’s a brief insight into our company’s rich history. Discover how it all began, how the company evolved, and the successes we’ve celebrated over the years. Experience Eibach up close, from 1943 to today.

Enjoy!

When the city center of Hagen in Westphalia was destroyed during a bombing raid, Heinrich and Maria Eibach, along with their one-year-old son Wilfried, were evacuated to a family friend in Rönkhausen. This is where the Eibach story begins.

Although the Eibach family was initially met with hesitation by the villagers and had to live under poor conditions for the next 10–12 years, they didn’t give up. At the time, no one could have imagined that their hard work and grounded nature would soon pay off.

For a long time, Heinrich Eibach couldn’t find work as a master tinsmith in Rönkhausen. Luckily, in 1951, he decided to start his own business in a small shed near the Rönkhausen train station. The company Heinrich Eibach was born.

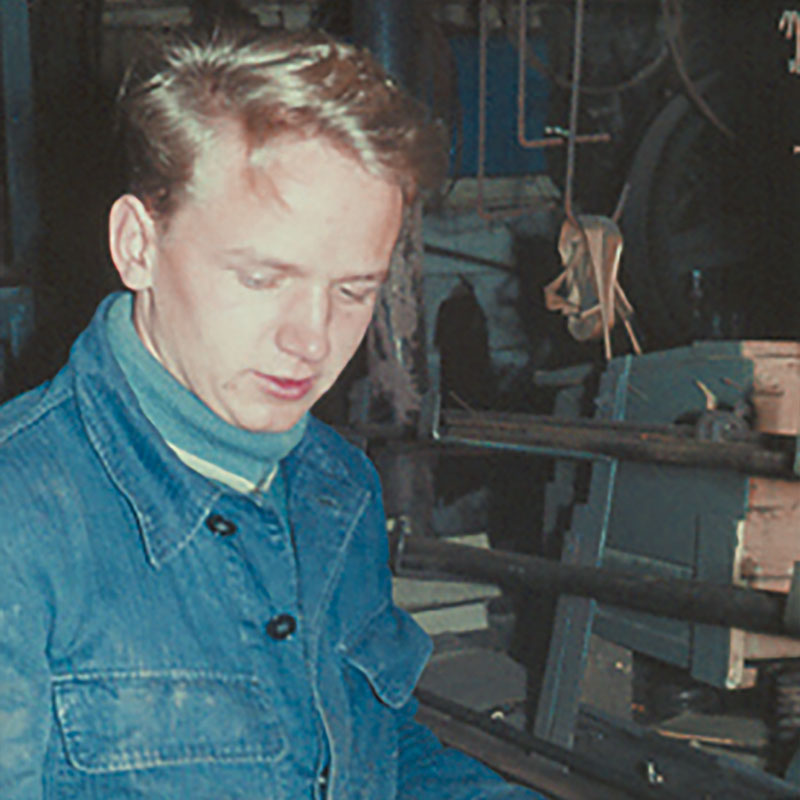

Eibach began to gain a foothold. Customers included Soeffge, Union Armaturen in Bochum, Vahle in Kamen, and Schotten in Duisburg. At the age of 16, Wilfried Eibach left high school to support his father Heinrich, who was suffering from emphysema.

By 1959, Eibach had four employees. The most important customer during this time was Sebu in Kreuztal, for whom they manufactured heavy coil springs. These were delivered several times a week at dawn using a van.

Annual turnover:

approximately €50,000

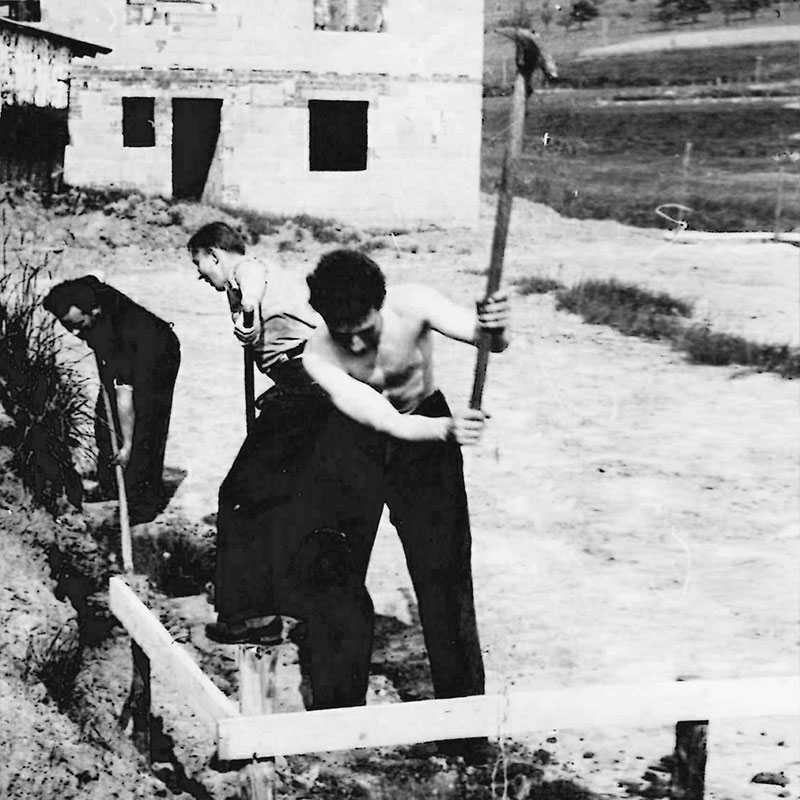

Thanks to its success, Eibach began to outgrow the small shed by the train station. Construction of a new, dedicated building in Rönkhausen-Thereck began.

For its first 20 years, Eibach primarily produced industrial springs. In 1970, Wilfried identified potential in specialized suspension springs for tuning vehicles. AMG, at that time still privately owned, became the first major customer in this segment.

Annual turnover:

approximately €1 million

The company had outgrown its original facilities. It was time to relocate all production and administration to the newly constructed Finnentrop facility at Lennedamm 1.

Over the years, the site expanded continuously. By 2020, Eibach had 25,000 m² of production, logistics, and office space. The site is now the headquarters of the Eibach Group, including its holding company.

At the Automechanika trade fair in 1986, we received significant attention, including from visitors from the USA. In October, Nina and Wilfried embarked on a U.S. tour, holding meetings in Florida and California, particularly at the SEMA show in Las Vegas, to understand the aftermarket.

It quickly became clear that distributing existing products alone would not suffice. A decision was made to establish a site in the U.S. with development, engineering, production, sales, and logistics. Guided by the motto: “The biggest risk in life is not taking any risks!”, Eibach North America (ENA) was founded in Irvine, California.

Annual turnovers (approx.):

1981: €5.7 million

1986: €13 million

1991: €24 million

1996: €38 million

In 1988, a new partnership began that continues to this day.

Together with Paul Bramford, owner of Magard, and his team, we embarked on a turbulent journey: from bankruptcy and reestablishment as Pilot Brands to further restructuring and ultimately the transformation into a subsidiary.

Today, Eibach UK is a strong member of the group, offering engineering services and a wide product range for OEMs, the aftermarket, motorsport, and special vehicles (Heavy Duty Suspension). Backed by four Eibach production plants (two in Germany, one in California, and one in China), our offering surpasses the competition.

This year marked the beginning of our story in Japan. Initially, we were represented by Tadaaki Hayakawa from UEC Union Enterprise Corporation, who at that time represented nearly all renowned European brands in our industry.

Later, Eibach Japan became independent but maintained UEC’s infrastructure.

In 2005, UEC faced challenges following the bankruptcy of a major client, prompting us to relocate to Kamakura at Dai Takewaki’s (General Manager) automotive workshop.

Facing further difficulties, we partnered with ABE Shokai in early 2014. This collaboration has been successful ever since and is supported by the Eibach Asia Pacific Center in Taicang, China.

During their first trip to Australia, Nina and Wilfried discovered that Lovells Springs was not a suitable distribution partner and ended the collaboration.

However, shortly after, they met Robert van Os, Lovells’ factory manager. The chemistry was immediate, and in 1997, Eibach Australia was established, moving into its own facility in Warriewood (Northern Suburbs of Sydney). Today, the subsidiary is successfully led by John Kayik.

In the USA, ENA continued to grow successfully. The building on Gillette Avenue in Irvine, which had been purchased simultaneously, became too small. This wasn’t a problem, as a perfect new location was soon found in Corona, California. The 15,000 m² brand-new facility is conveniently located at the intersection of Freeways “15” and “91.”

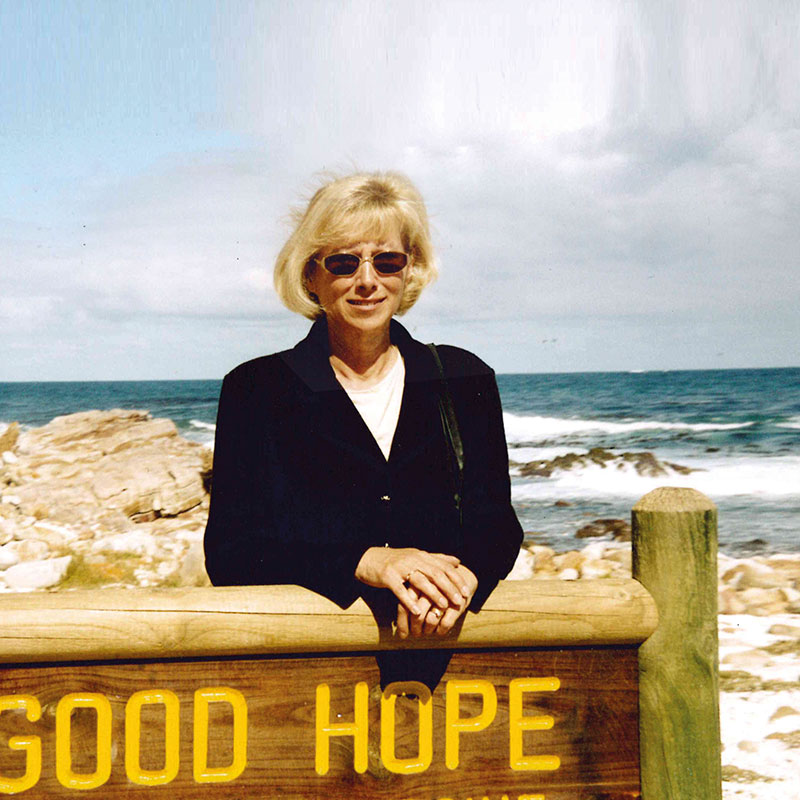

In 2003, Nina and Wilfried traveled to South Africa to get to know the sister company of EOT in Port Elizabeth and explore the potential for their suspension products.

During their visits to the then-importer Chad Wenzel, it became clear that he lacked the necessary distribution network. However, due to high local demand for our solutions, we established Eibach South Africa within the existing EOT building in Port Elizabeth.

In 2006, Nina and Wilfried Eibach established the non-profit Eibach Foundation to support charitable initiatives.

Annual turnover:

approximately €50 million

In 2008, we founded the Chinese subsidiary Eibach Springs Taicang and purchased land near Shanghai.

Shortly after the financial crisis ended, we constructed a 4,000 m² production and administrative building in Taicang.

By 2012, the first products were being manufactured at the new site. Eibach Springs Taicang has since grown to become the Eibach Asia Pacific Hub.

At the German site, the Wiethfeld plant was built, featuring over 10,000 m² of production and office space in a newly developed industrial area just 6 km from the company’s headquarters.

During the plant’s early phase, new products were developed, and new customers were acquired.

Despite the COVID-19 crisis, a new ERL warehouse adjacent to the Wiethfeld site was completed within just eight months. Operations began on January 4, 2021, on a 3,000 m² area.

In 2021, the long-standing combination of shareholders and management at Eibach Industries GmbH (Holding) included:

With the world still grappling with COVID-19, we postponed our traditional anniversary celebration (Schützenfest!) for the global Eibach family to 2022.

Nevertheless, there was still plenty to celebrate: in our anniversary year, the Eibach Group and its approximately 600 employees aimed for a group turnover of around €100 million.

From our beginnings in a small office in Irvine, California, to our own 14,400 m² production facility in Corona, California, we have always focused on meeting the needs of enthusiasts around the world. This remains true today as we begin construction of our US production facility to enable the expansion of our in-house developed and manufactured “Made by Eibach” products.

The new 1,200 m² expansion will house the production of high-performance suspension systems such as (truck and UTV) track extensions, Pro-Truck shock absorbers, and even our new Pro-Truck upper link kits.

With this groundbreaking ceremony, we look to the future with excitement.

The current management of the holding company and Heinrich Eibach GmbH.

Markus Simon, Jürgen Schulte, Wilfried Eibach (Chairman), Benjamin Keogh

Over the course of 75 years, Eibach has steadily developed into an internationally active company. Today, the Eibach Group employs around 700 people and is considered a leading manufacturer of suspension and chassis systems as well as special technical springs.

The Eibach Group, with Eibach Industries GmbH as its holding company, has its own production sites in Europe, North America, and Asia, as well as engineering and sales companies in several countries, and serves Eibach customers with the support of regional partners in a further 80 countries worldwide. With 75 years of existence, Eibach can look back on a mature corporate structure.

Der neue Ford Ranger Wildtrak in der “Eibach Edition” wird in Zukunft vor allem als Zugfahrzeug für unsere Modulbox zum Einsatz kommen. Selbstverständlich haben wir dem Ranger schon unsere Eibach Pro-Lift-Kit Höherlegungsfedern und Pro-Spacer Spurverbreiterungen verbaut! Das Pro-Lift-Kit für den Ford Ranger optimiert das Fahrzeug auf ganzer Linie und bringt an Vorder- und Hinterachse ca. 30-35 mm mehr Bodenfreiheit. Unser Partner Hansen Styling Performance Parts ist Spezialist für Off-Road Fahrzeuge – keine Frage, dass die Firma Hansen ein großes Interesse an unserem Ford Ranger hatte. Neben diversen Anbauteilen für die Karosserie und Lichtleisten auf dem Dach sowie an der Stoßstange, haben wir die W-TEC EXTREME “BLACK EDITION” Alufelgen auf dem Ford montiert. Ummantelt wird die Felge von Yokohama Reifen. Der GEOLANDAR A/T G015 gilt als außergewöhnlicher All-Terrain Reifen mit fortschrittlichsten Technologien. Er ist speziell für Pick-Ups und Fahrzeuge mit Allrad Antrieb entwickelt und zeichnet sich durch seine fortschrittliche Laufstreifen-Technologie mit 3D-Lamellen, optimiertem Profil-Negativ und neuer Pitch-Variation aus.

stabilizers

Attachment components

stabilizers