PRODUCTION

Raw material availability: In our warehouse we stock coils and bars in approximately 4000 different types, differentiating in specifications, dimensions, surface grades and similar. This extensive stock of raw materials ensures a premium disposability for prototypes and single pieces as well as for small, medium and large production runs.

Quality and flexibility: It is our top priority to combine highest quality with maximum flexibility.

CNC manufacturing technology: The use of state-of-the-art CNC technology in the entire production allows to minimize set-up times, ensures highest precision, small tolerances and optimum surface quality.

Some significant production features:

- State-of-the-art CNC cold forming of springs , using very high tensile strength, alloyed, oil-tempered spring materials up to 19 mm wire diameter; above 19 mm and up to 25 mm wire diameter, using our pre-hardened patented cold-drawn wire

- CNC Cold forming of springs up to 32 mm wire diameter, using annealed materials (for example 50 CrV4) in coils, heat-treated after winding

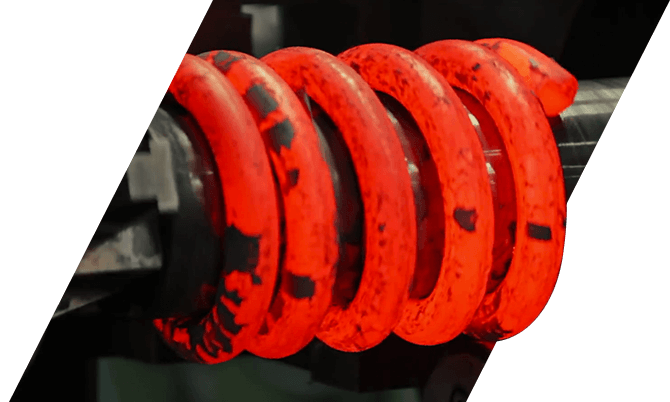

- Hot forming of coil springs up to 55 mm bar diameter (bar length max. 8.30 m)

- State-of-the-art grinding- and production machinery through implementation of our own production knowledge

- Chamfering of spring ends (in- and outside) by robots and especially developed handling systems

- Internal tool- and gauge shop

- Improvement of the dynamic durability through state-of-the-art shot peening techniques including thermal- and stress peening

- Relaxation minimization through controlled heat-setting processes

- Economic in-house developed CNC bending technologies for stabilizer bars, made of prehardened solid or tubular material for small batch sizes and series, mostly used without additional tools

- Stabilizer end processing, using in house developed robot-supported systems

- Vulca-bonding process: especially designed by our engineers for the fixation of rubber bus hings on stabilizer bars

- Zinc phosphating with subsequent powder coating (polyester | epoxy resin) or EPD as alternative

- Extensive range of colors available, including UV-resistant powders

- Product identification through pad-, ink-jet printing or laser marking

For just-in-time- | just-in-sequence deliveries, compliance with call-off- and delivery plans as well as for the implementation of economical production batches, we offer an extensive, barcode-controlled warehouse for finished goods. This includes Eibach standard suspension- and industrial products as well as custom spec springs for call-off-orders.