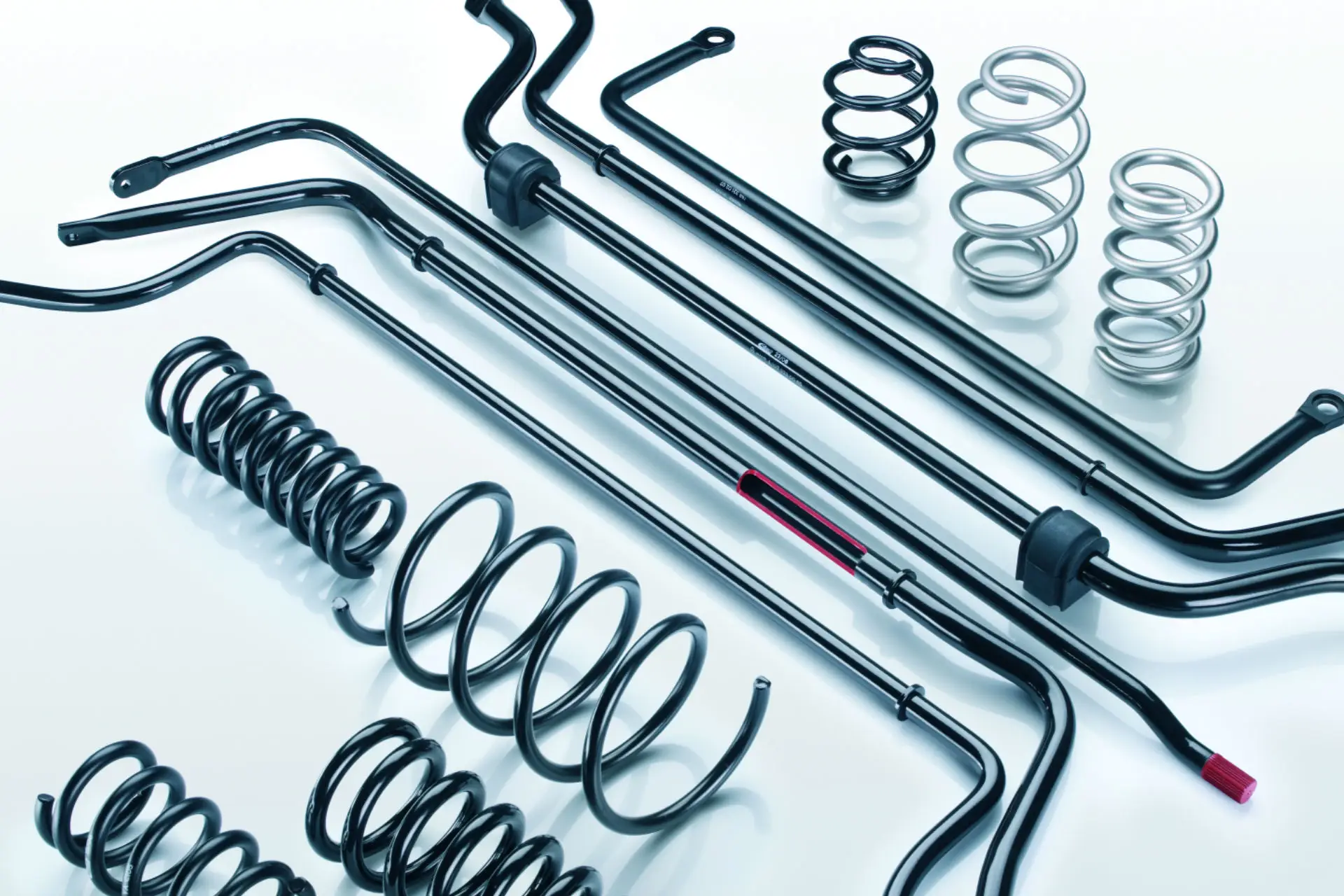

Stabilizers are an important component of vehicle suspension systems. Solid stabilizers provide maximum stability, even with complex routings and limited installation space.

With their robust design, they integrate seamlessly into various vehicle architectures and ensure more agile cornering and more precise steering behavior.

Compared to solid stabilizers, those manufactured from precision steel tubing are designed to meet the automotive industry’s strict lightweight construction requirements and developed for the most demanding applications. Depending on the application, with a constant or variable cross-section, we ensure uniform stress distribution and high structural integrity. Reduced weight with maximum efficiency and control.

Our split stabilizers are key components of active roll stabilization systems, which resolve the traditional trade-off found in conventional stabilizers (driving dynamics vs. ride comfort).

Meeting the most demanding shape and positional tolerances, precise connection geometries on both the actuator and vehicle side are a central focus.

Active roll stabilization systems enable more dynamic driving behavior and increased agility while enhancing driving safety and overall ride comfort.

Eibach spherical bearings for mounting conventional stabilizers are used wherever extreme stiffness and limited installation space meet – for example in sports cars, hypercars, or special vehicle construction. They deliver maximum performance with minimal space requirements.

Our post-vulcanized elastomer bearings form a permanent and durable bond with the coated stabilizer surface. They prevent relative movement and therefore avoid corrosion at the bearing interface as well as noise generation.

In general, these components show significantly lower wear and also simplify parts handling during assembly on the production line at the customer’s facility.

The stiffness characteristics of the PV bearings can be individually adapted to the specific application.

These fastening elements are used to attach the stabilizer bearing to the vehicle chassis. The brackets are typically sheet metal-formed parts and can be designed as one- or two-piece versions.

In the case of a two-piece design, clinching (mechanical joining) allows the assembly to be delivered ready for installation, including the bearing as a complete sub-assembly (ZSB).

Linear springs provide constant spring rates for precise handling and stability – ideal for sporty vehicles. Progressive springs adapt to the load, enhancing comfort and efficiency. Eibach delivers premium solutions tailored to individual driving needs – for a driving experience at the highest level.

stabilizers

Attachment components

stabilizers

Der neue Ford Ranger Wildtrak in der “Eibach Edition” wird in Zukunft vor allem als Zugfahrzeug für unsere Modulbox zum Einsatz kommen. Selbstverständlich haben wir dem Ranger schon unsere Eibach Pro-Lift-Kit Höherlegungsfedern und Pro-Spacer Spurverbreiterungen verbaut! Das Pro-Lift-Kit für den Ford Ranger optimiert das Fahrzeug auf ganzer Linie und bringt an Vorder- und Hinterachse ca. 30-35 mm mehr Bodenfreiheit. Unser Partner Hansen Styling Performance Parts ist Spezialist für Off-Road Fahrzeuge – keine Frage, dass die Firma Hansen ein großes Interesse an unserem Ford Ranger hatte. Neben diversen Anbauteilen für die Karosserie und Lichtleisten auf dem Dach sowie an der Stoßstange, haben wir die W-TEC EXTREME “BLACK EDITION” Alufelgen auf dem Ford montiert. Ummantelt wird die Felge von Yokohama Reifen. Der GEOLANDAR A/T G015 gilt als außergewöhnlicher All-Terrain Reifen mit fortschrittlichsten Technologien. Er ist speziell für Pick-Ups und Fahrzeuge mit Allrad Antrieb entwickelt und zeichnet sich durch seine fortschrittliche Laufstreifen-Technologie mit 3D-Lamellen, optimiertem Profil-Negativ und neuer Pitch-Variation aus.